You may have experienced that sudden “shock” when touching a plastic object or noticed sparks when putting on a polyester sweater. This is electrostatic discharge (ESD), which can cause significant problems, especially for electronic components or in environments like laboratories or chemical reactor zones.

In a world dominated by electronics and industrial technology, ESD control is becoming increasingly important. Electrostatic discharges can damage components, leading to financial losses, lower product quality, and increased returns(1). To address these challenges, engineers are increasingly turning to ESD materials—and we have joined them, producing such materials for years.

(1) Elektryczność statyczna – przyczyny i przeciwdziałanie – Wiadomości – Wortal Plastech

What are ESD Plastics?

ESD plastics are specialized polymer materials designed to dissipate or control the accumulation of electrostatic charges. Standard plastics, such as polypropylene (PP) or polyvinyl chloride (PVC), act as insulators and easily accumulate charges, leading to uncontrolled discharges. Surprisingly, we use these very materials in our production.

With the addition of special antistatic agents, our materials reduce electrical resistance, allowing electrostatic charges to dissipate gradually, minimizing the risk of discharges.

We choose PP and PVC not only for their cost-efficiency in production but also because they are fully recyclable.

How Do ESD Plastics Work?

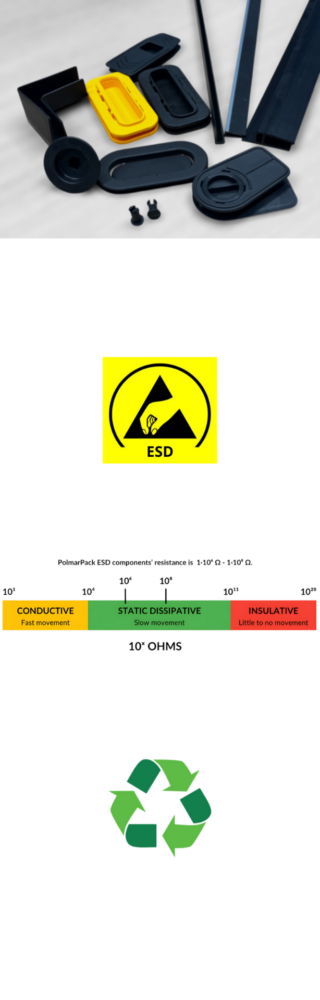

ESD plastics are categorized into three types based on their conductivity levels:

A key feature of these materials is their ability to dissipate electrostatic charges without generating sparks, which is crucial in both production processes and for protecting electronics(2).

Where Are ESD Plastics Used(3)?

ESD plastics are used in a variety of industries, including:

ESD Packaging and Components

The production of ESD packaging is not much different from standard manufacturing processes. Our injection molding and extrusion technologies effectively handle these materials. We offer a wide range of ESD products, including edge profiles, handles, corners, and closures. Our designs feature structural panels with the appropriate ESD properties. What sets us apart? We can manufacture soft ESD components in various colors—not just black!

A crucial part of production is thorough quality control, including surface resistance testing.

Why Use ESD Plastics?

(4) Zielony pakiet 2030 – 25 poprzednich 25 lat – Plastech.pl

Conclusion

ESD plastics play a key role in protecting against electrostatic discharges across many industries—from electronics to the chemical sector. They make production processes and products safer and more reliable. If you’re designing or manufacturing devices, consider using ESD plastics to safeguard your products from the harmful effects of electrostatic discharges.